Our equipment

Once your project has been validated, we ensure the manufacture of your finished product. Our production facilities allow us to adapt to the specific characteristics of each food supplement:

- Water softeners and an osmosis unit to guarantee the quality of the water used in our processes.

- A maceration facility

- 3 filling lines for ampoules and single-doses of 5 to 15 ml

- 2 filling lines for bottles from 20 to 1000 ml

- 2 filling machines for single-dose 10 ml

- 2 filling machines for 25 ml shots

- 2 filling lines for vials

- 2 filling lines for ampoules

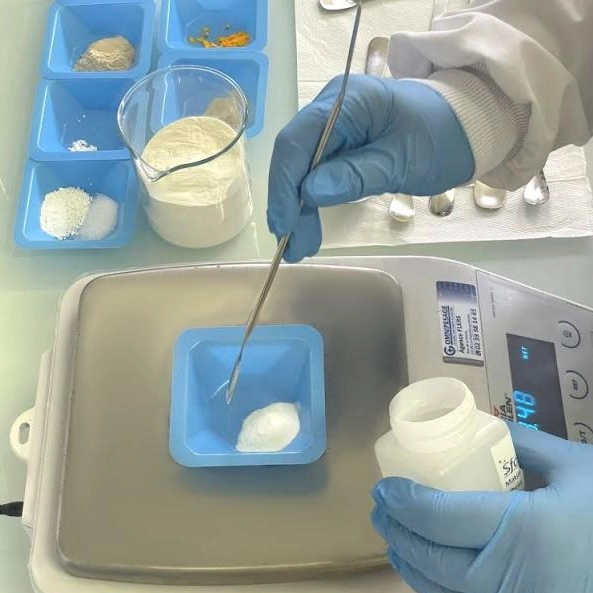

Weighing

Aqueous extraction and mixing

Filling of ampoules

Single-dose filling

Heat treatment by autoclave

Heat treatment using flash pasteurisation

Packaging

The complete handling of orders from the supply of raw materials to the final packaging, allows a global control of the quality of the products delivered.

We use different heat treatment techniques depending on the formulas, in order to respect the naturalness of the ingredients:

- 2 autoclaves

- 5 pasteurisation tanks

- 2 tyndalisers

- 2 flash pasteurisers